Quest...The Home Of Power Semiconductors

We are networked with leading technology corporations, top-tier institutes, and currently, we take pride in our collaboration with the Griffith University of Queensland.

At Quest, our product range is diverse and cutting-edge.

We offer high voltage switching SiC technology which is paramount for transformative applications such as electric vehicles, renewable energy , defense and aerospace.

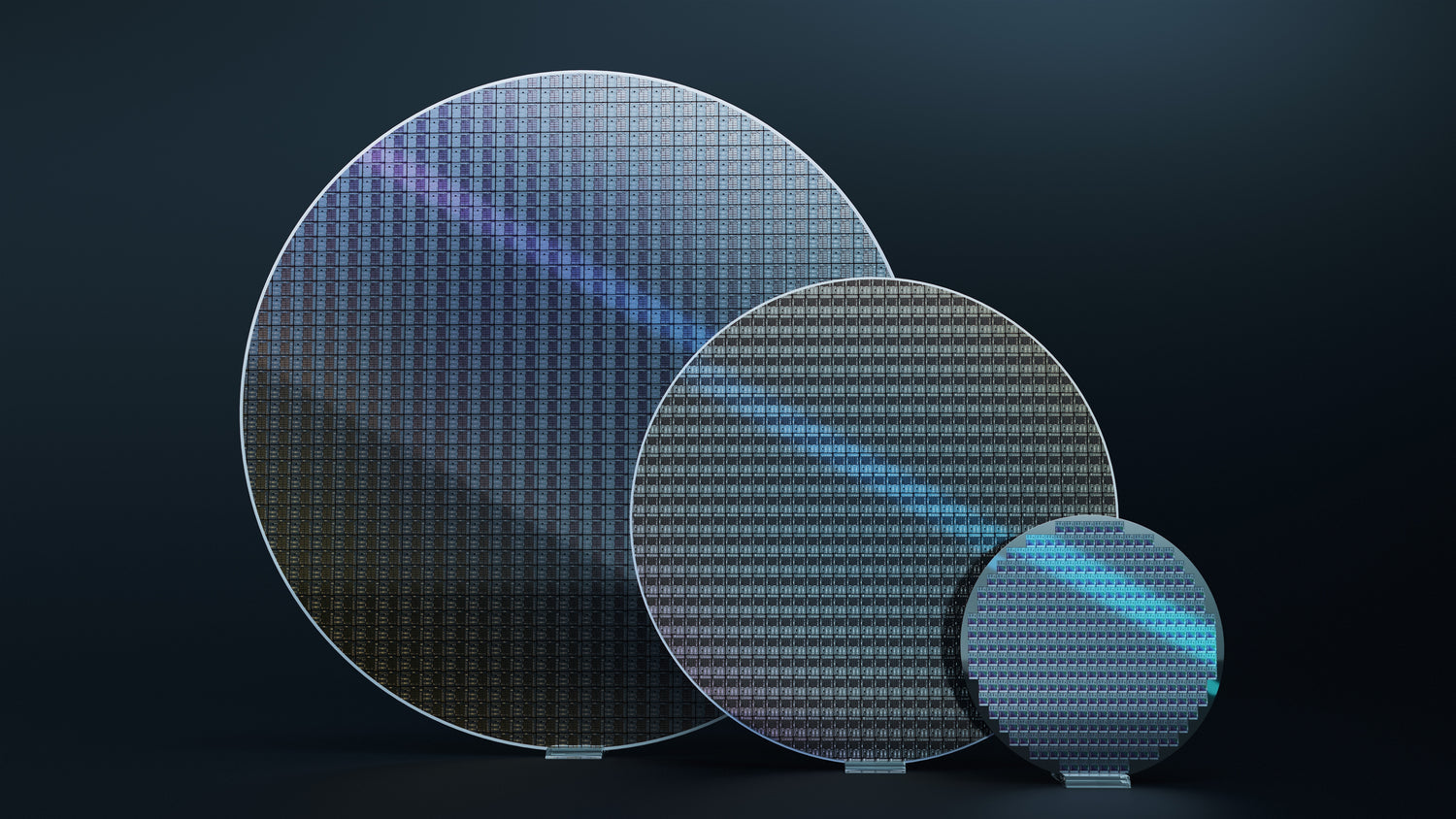

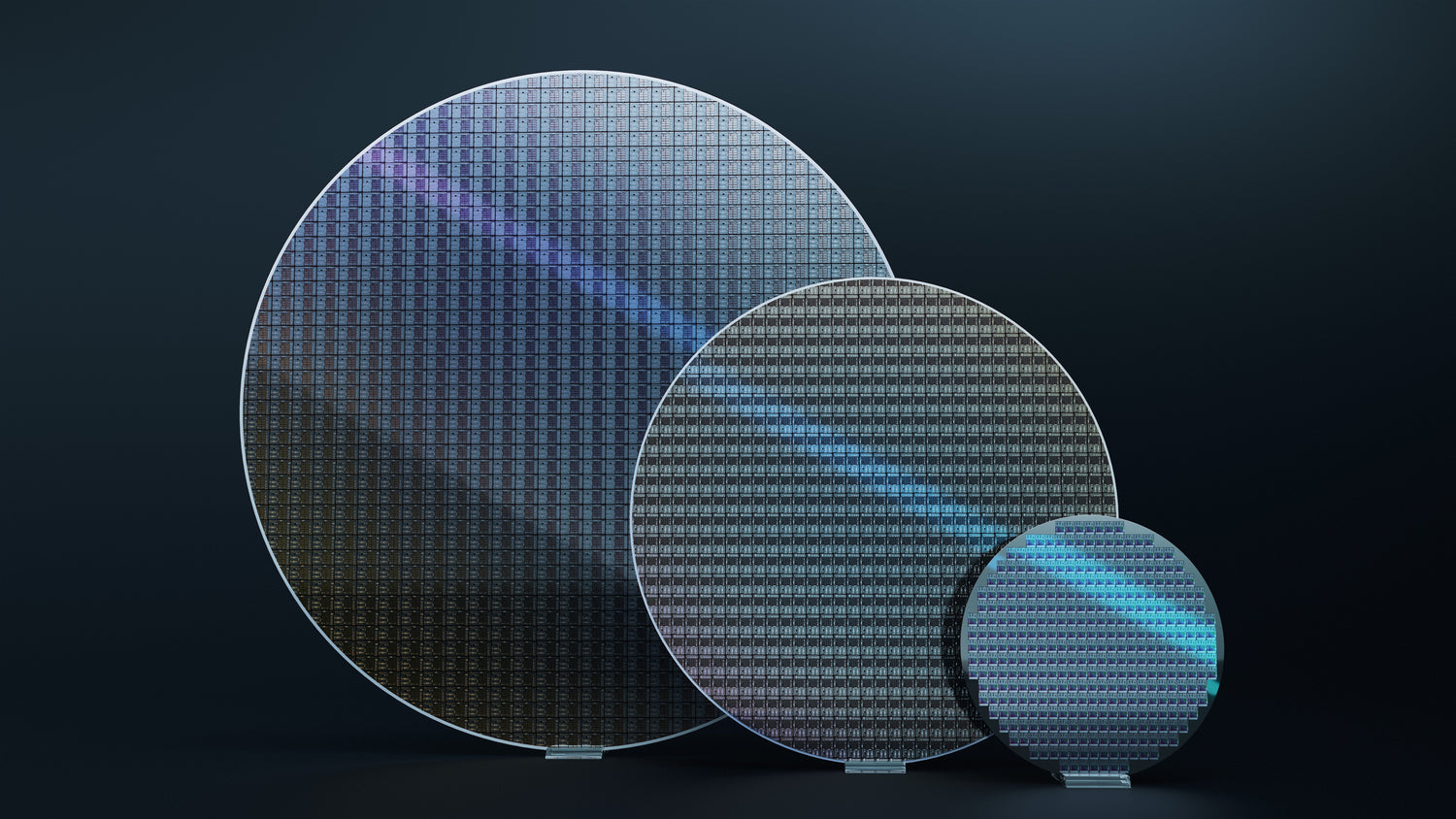

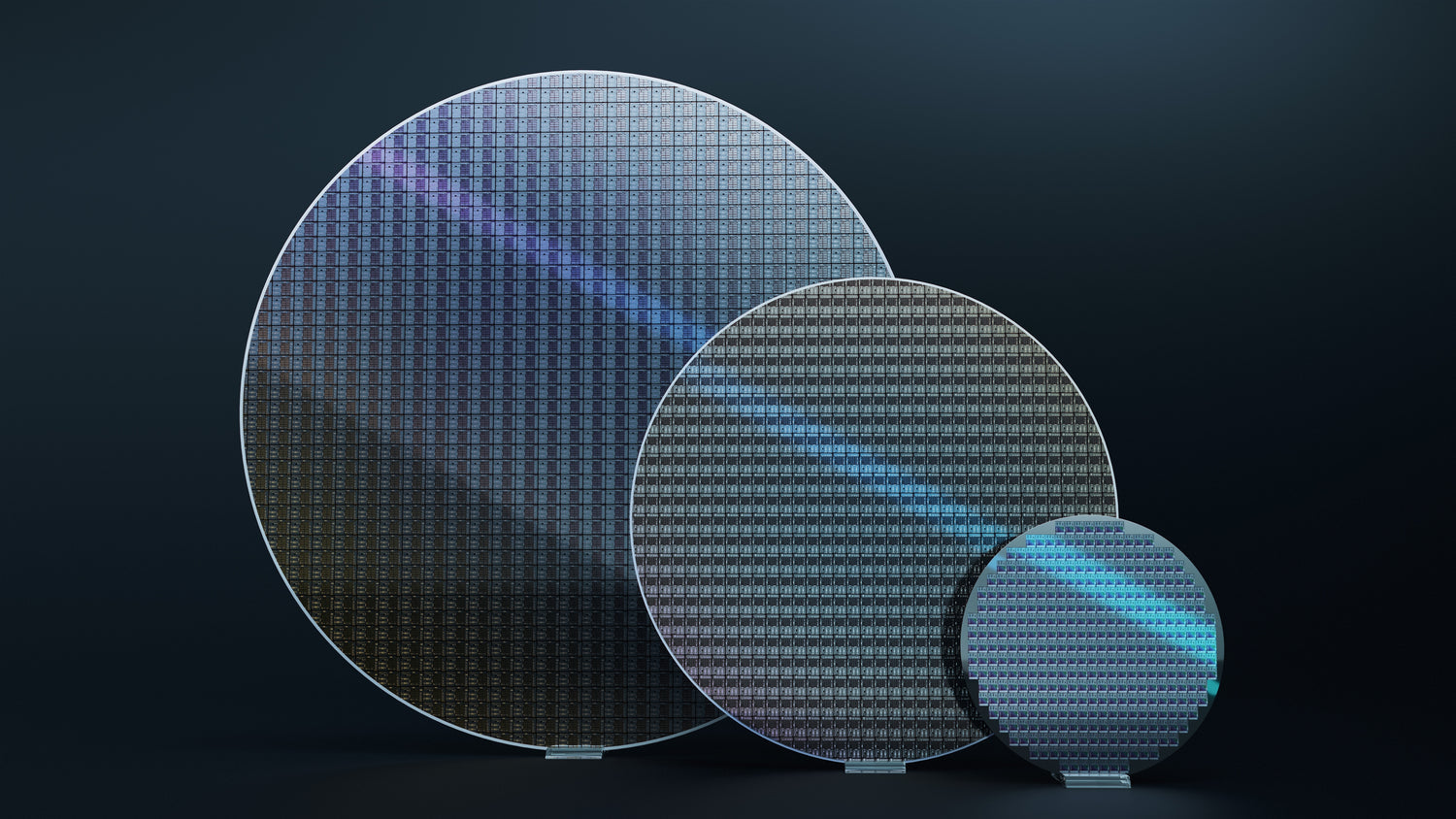

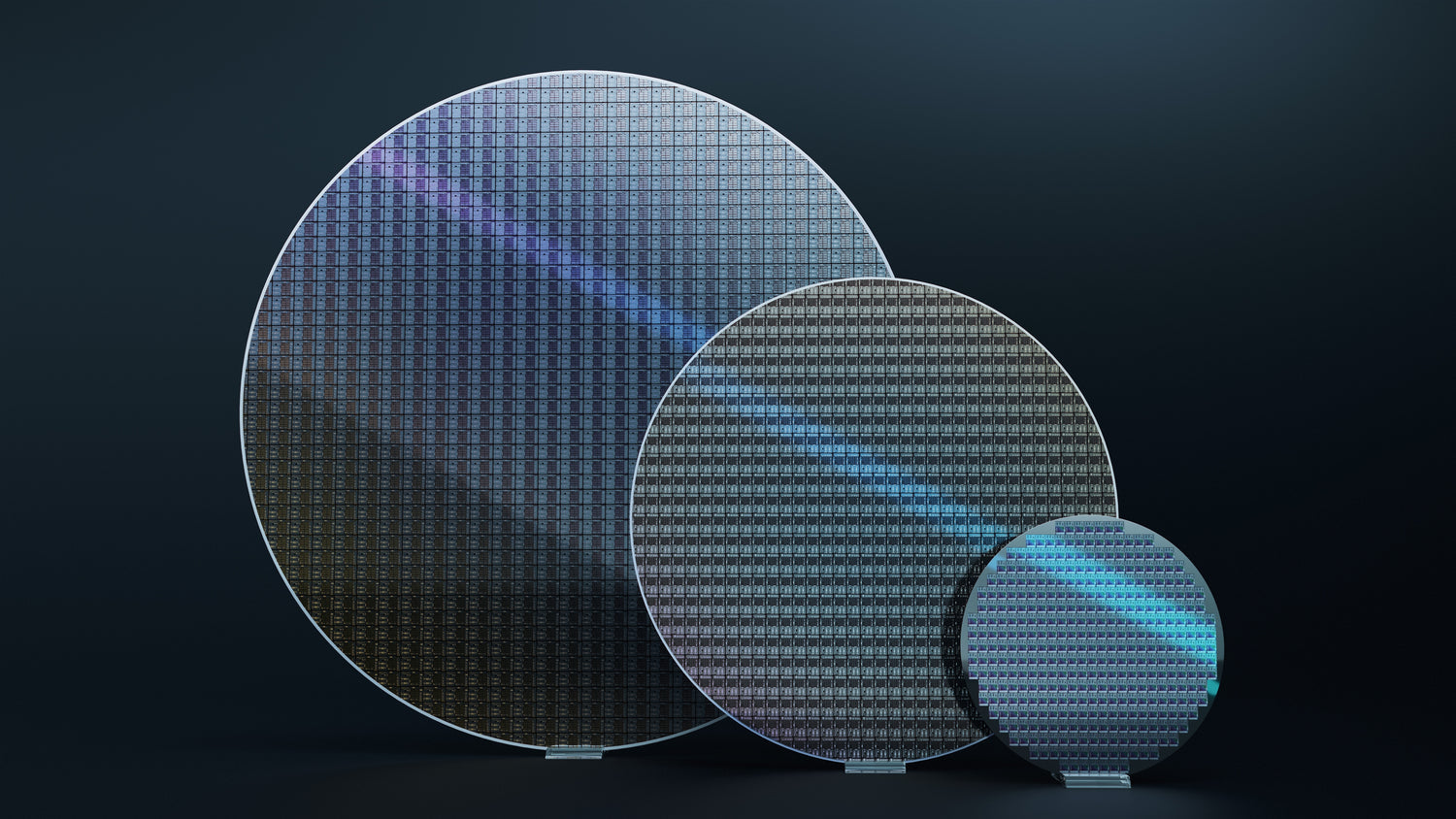

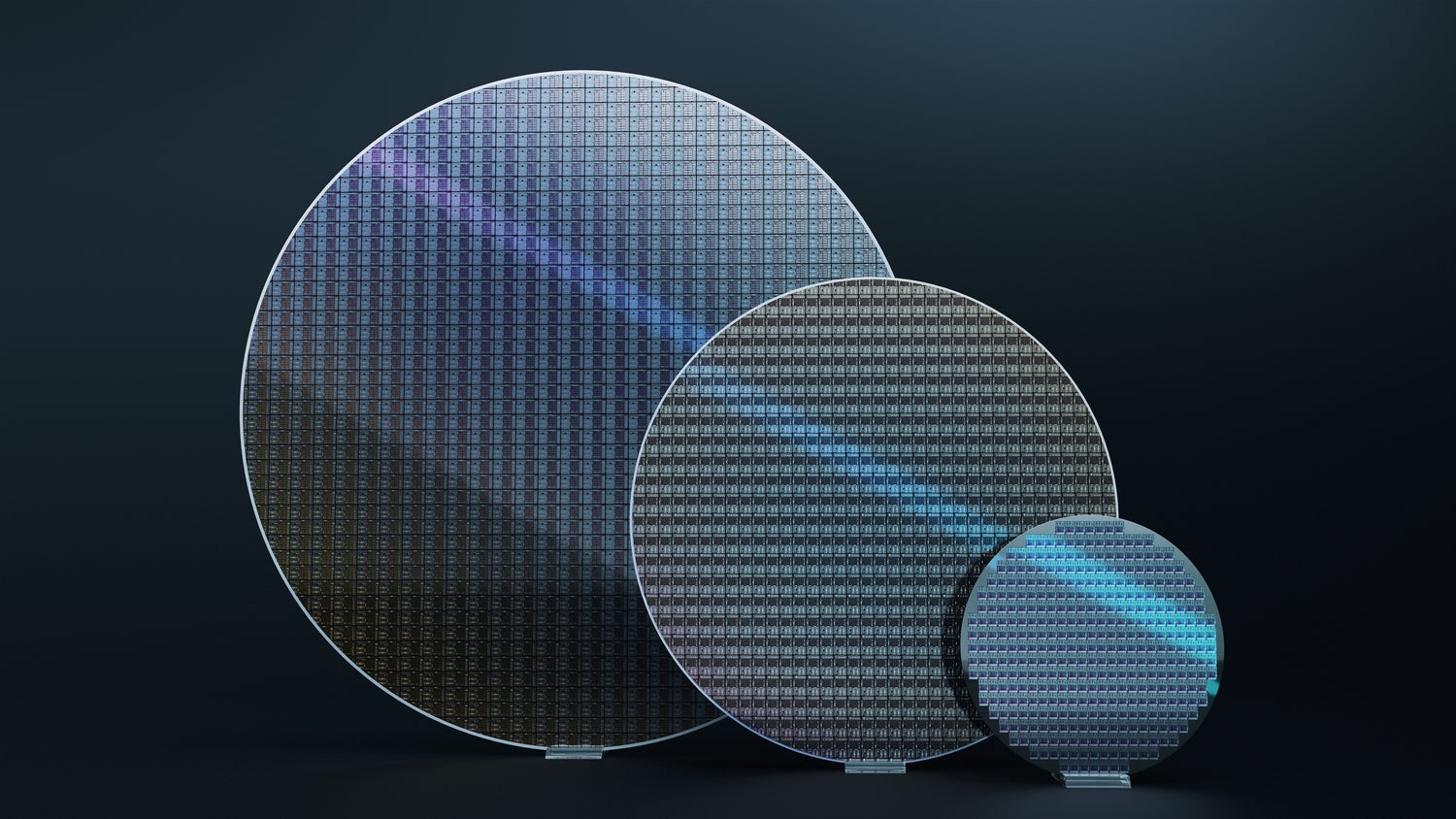

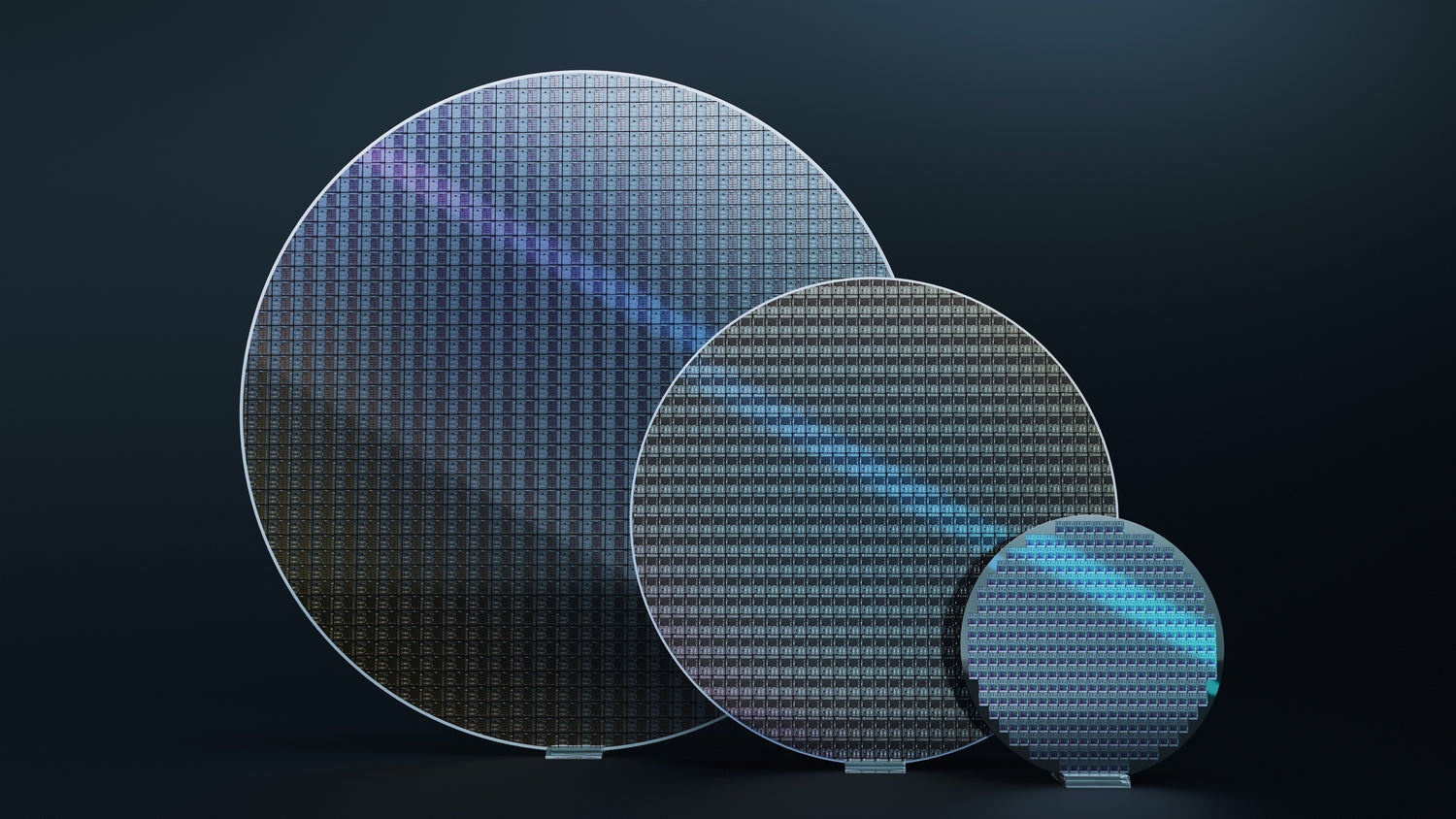

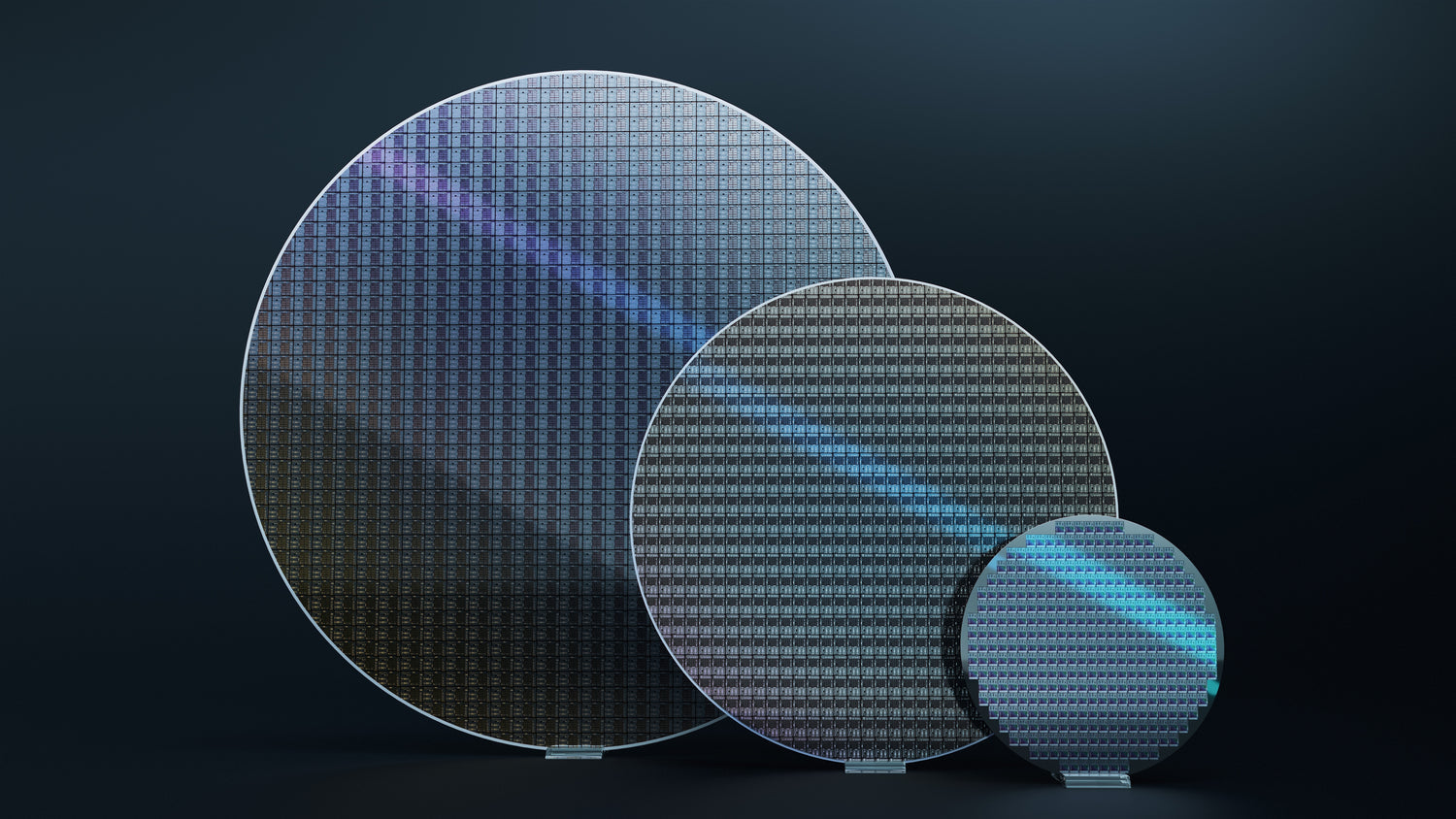

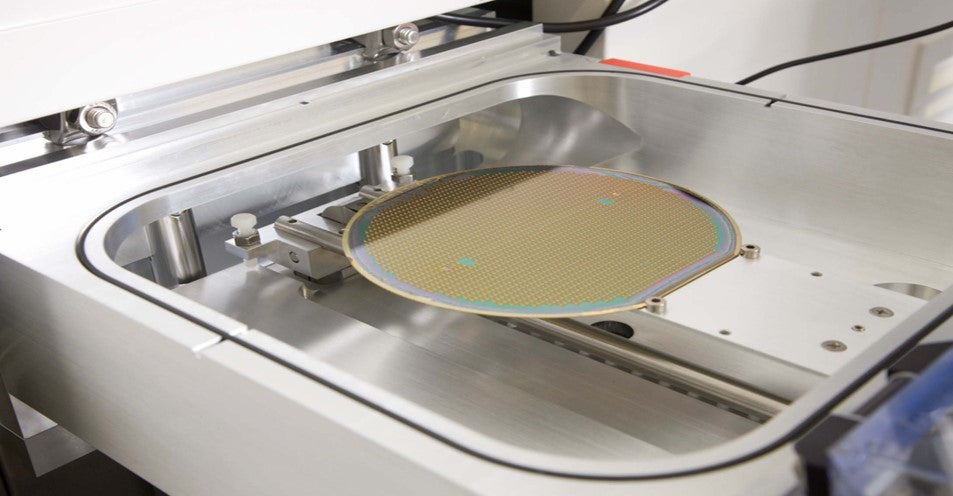

Wafers and bare die

The Home Of Power Semiconductors

Quest stands at the forefront with leading technology and ethical business acumen.

SiC SBDs are small semi-conductor devices or one-way switches that are widely used in power conversion systems that rely heavily on the characteristics of silicon carbide – in that it is highly thermally conductive, has an extremely low coefficient for thermal expansion and is also highly resistant to thermal shock. In general, silicon carbide SBDs are considered to be significantly more efficient than standard diodes, being able to operate at high current density with a low forward voltage drop that result in less wasted energy.

The downside of silicon carbide diodes is that the production process has traditionally been complicated and relatively costly but through the research collaboration that Quest have established with QMF, new patented processes are now available that dramatically speed up and reduce the cost of the process. Incorporating production steps that are standard procedure in the manufacture of SiC wafers has revolutionized the design of these components and also allows customer specifications in regard to forward voltage and current rating to be facilitated in a timely and cost-effective manner. Low fabrication time and reduced costs all results in lower prices for the customers and the product will be in high demand particularly in the production of solar inverters, motor drives, electric car chargers and other users of uninterruptable power supplies.

At the present time, Quest can provide SiC SBDs that operate within a voltage range of 600 – 4500 v but the research in which we are involved indicates that even higher ranges are possible. Currently available in the TO247 package or as a wafer level Bare Die silicon carbide Schottky diodes which are also in the voltage range from 650 -4500v.

Quest has established an outstanding reputation within the industry for delivering exactly what the customer needs, regardless of the size of their operation or the platform on which they operate. Whilst leading the way as SiC Schottky Diode manufacturers the operation extends to power modules, TCIGBT’S, wafers in 4’’, 6’’ and 8’’, sensors, SiC membranes and Jfets - versatility is one of the keys to the business model. Quest is happy to listen to your specific requirements and provide precisely what you require – whatever it is. Feel free to contact us to discuss your needs now. Furthermore, with centres in Australia, New Zealand, Scotland and Spain, Quest and affiliates Semefab can assure customers of a global network of customer service and support across all time zones ensuring your continuing peace of mind.

In collaboration with our affiliate company, Semefab, Quest has a mission to produce and provide power modules and associated products to meet the specific needs and applications of our customers. And as leading SiC Schottky diode manufacturers our goal is to provide a range of SiC SBD, SiC wafers and Bare Die SiC Schottky diodes that deliver on quality and price whilst still maintaining the highest levels of SiC performance.

The advent of affordable silicon carbide diodes has witnessed an upturn in performance levels, as this family of diodes offer superior switching performance efficiency, greater power density whilst also delivering low forward voltage drop high surge voltage capabilities and a positive temperature co-efficient – and all at lower system costs than previously achievable.

If you need Bare Die SiC Schottky diodes, here at Quest, our selection within the high voltage range of 650V to 4500v are unequalled elsewhere in the market. Our new TCIGBT power modules complement our SiC Schottky barriers diodes and together can offer the most reliable effective high voltage switching technology on the global market.

With an increasing number of applications in a wide range of industries such as renewable power and the automotive industry, demand for high performance silicon carbide Schottky diodes is set to increase accordingly and Quest is at the fore front of meeting supply. No matter the size of your operation, if you require industrial solutions, such as silicon carbide SBDs, Quest have the expertise and experience of manufacturing SiC wafers to customer led specifics, to be of assistance in a cost effective and timely manner. Let Quest help you optimise your products in a global market.

Sitting at the forefront of innovative technology in the field of power semiconductors, you will find Quest, a Queensland based company that excel as SiC Schottky Diode manufacturers serving the ever- growing market for silicon carbide diodes not just here in Australia, but across Asia, South East Asia and the USA. Our new facility here in Australia is complemented by our European facility enabling us to provide global solutions to newly developing industries such as electric transport and the generation of renewable energy.

Constantly striving for more efficient innovations within Sic Schottky barrier diodes, our speciality is in developing high voltage SiC Schottky diodes which have many applications and are instrumental in pushing our society towards a cleaner and more efficient future. However, at Quest, we are not limited to only manufacturing Bare Die silicon carbide Schottky diodes and other incarnations of silicon carbide SBDs but have a wide-ranging menu and are a high quality IGBT power module manufacturer and supplier, with the next generation of TCIGBT devices out early 2024.

Our commitment to our customers in unquestionable; our faultless standards of customer care and our insistence on excellence within all of our products - Sic wafers, Sic SBDs, IGBTs, MOSFETs and TCIGBTs contributes to our forging long lasting relationships with many of our customers. Cutting edge technology will provide us all with the potential for a better future and Quest are proud to be a part of this revolution. We manufacture and provide off the shelf Schottky silicon carbide barrier diodes here in Australia but can also create the silicon carbide Schottky diode that exactly meets your needs , available in numerous packages or simply as a wafer or bare die.